Second life for used batteries.

Text from Phillip Bittner

Illustrations from Yannic Hefermann

March 2019

The requirements on batteries in electric vehicles are extraordinarily strict. At Volkswagen, the quality demands on these high-tech products are equally so. This is why various approaches are employed to research further applications for batteries after their first use in the vehicle.

Accelerating after a traffic light, recuperation while braking, a quick stopover at a fast-charging station or night-time charging using the wall box at home. All of these place demands on batteries. As does the transition between minus temperatures in winter and 30 degrees in the heat of summer. The batteries in an electric vehicle operate under extreme conditions such as moisture, the influence of forces and vibration. Volkswagen however guarantees its customers – with the e-up!, for example – that, after eight years or 160,000 kilometres, 80 per cent of the initial battery capacity will still be available. After use in electric vehicles, battery capacity is still more than adequate for other applications. A new working life then awaits as so-called second-life batteries.

“The extension of the working life plays a central role in our Volkswagen group battery strategy.”

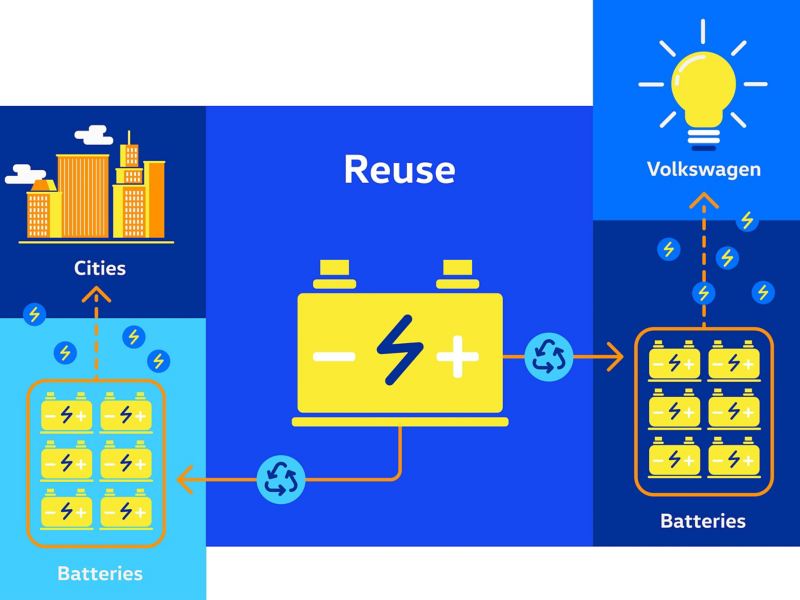

Reuse.

“In addition to an optimal recycling process, the extension of the working life plays a central role in our group battery strategy. In principle, the batteries should be repaired or reconditioned in the first instance or be converted into second-life projects for complete reuse,” says Tobias Enge, a group strategist in the business field of e-mobility & infrastructure. “Further processing in alternative environments – for example into mass-storage devices – is being researched as part of use cases and developed for practical applications.” Thus, within the Volkswagen Group, there are numerous second-life mass-storage projects. Here, used vehicle batteries are bundled and employed as giant batteries – both in Volkswagen plants and in cooperative projects with supply companies and cities. The battery life can be extended with these kinds of additional applications.

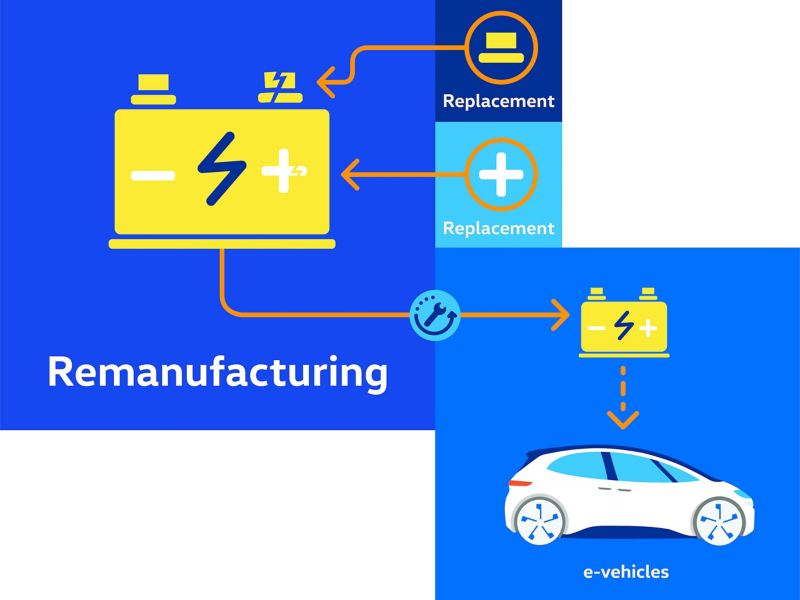

Remanufacturing.

In addition to reuse – further use outside of the vehicle – Volkswagen also relies on remanufacturing. In this application, the used batteries are made suitable for employment in electric vehicles again through the replacement of individual components. Alternatively, further use in stationary storage is possible here, too, after partial disassembly of the battery into its modules.

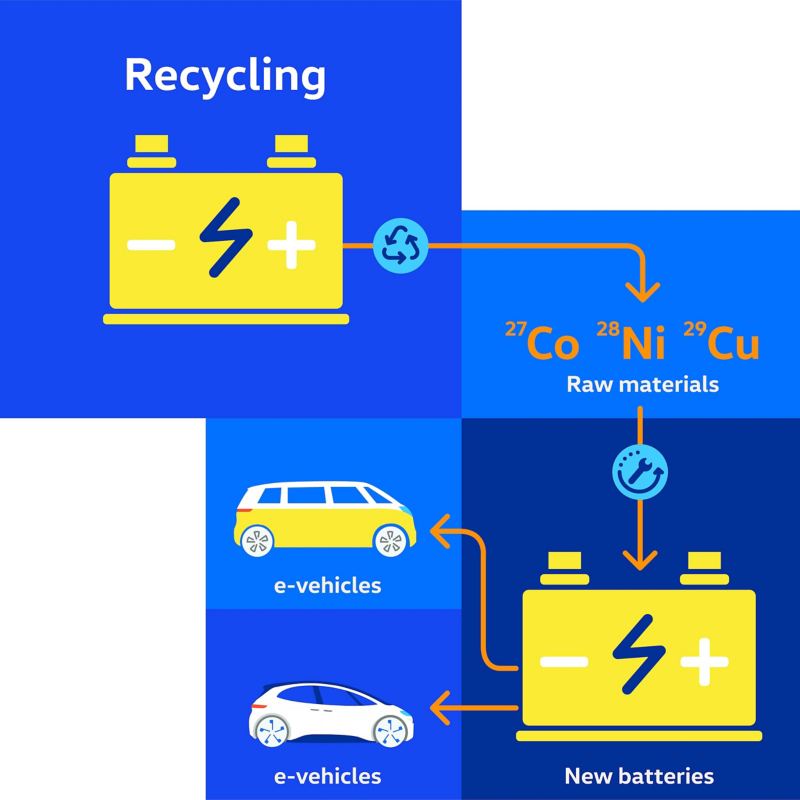

Recycling.

Sooner or later, batteries must be recycled after use. This is carried out for all batteries employed in the group. In cooperation with a number of recycling partners, Volkswagen is building an effective and safe recycling procedure in all markets. “The batteries are dismantled, crushed and reprocessed. Here, raw materials such as nickel (28Ni), copper (29Cu) and cobalt (27Co) are recovered in large quantities and can then, for example, be reused in the production of new battery cells,” says Tobias Enge. An important contribution to a sustainable mobile future, because effective recycling conserves important resources required for the manufacture of batteries.

As soon as there are also enough reusable vehicle batteries with the increasing number of electric vehicles, the intelligent strategy of recycling and reuse will in due course be employed across the board. With this approach, the Volkswagen Group is well placed to sustainably conserve important resources. This kind of sustainable approach increases enthusiasm for electric mobility and interest in e-models from Volkswagen.

e-up! fuel consumption in kWh/100 km: 11.7 (combined); CO₂ emissions in g/km: 0 (combined); efficiency class: A+.

Information in accordance with directive 1999/94/EC as amended: further information on the official fuel consumption and the official specific CO₂ emissions of new cars can be found in the “Guide on the fuel economy, CO₂ emissions and power consumption of new passenger cars” available free of charge at all points of sale and from DAT Deutsche Automobil Treuhand GmbH, Hellmuth-Hirth-Strasse 1, D-73760 Ostfildern, Germany, or at www.dat.de.